Throughout its 40-year journey of formation and development, accompanying the common development of the country, Vietnam National Oil and Gas Group and PetroVietnam Construction Joint Stock Corporation, Petroleum Equipment Assembly and Metal Structure Joint Stock Company (PVC-MS) has achieved many proud achievements, which can be summarized by the following notable highlights:

1. Participating in the construction of Vietnam's first jacket platform

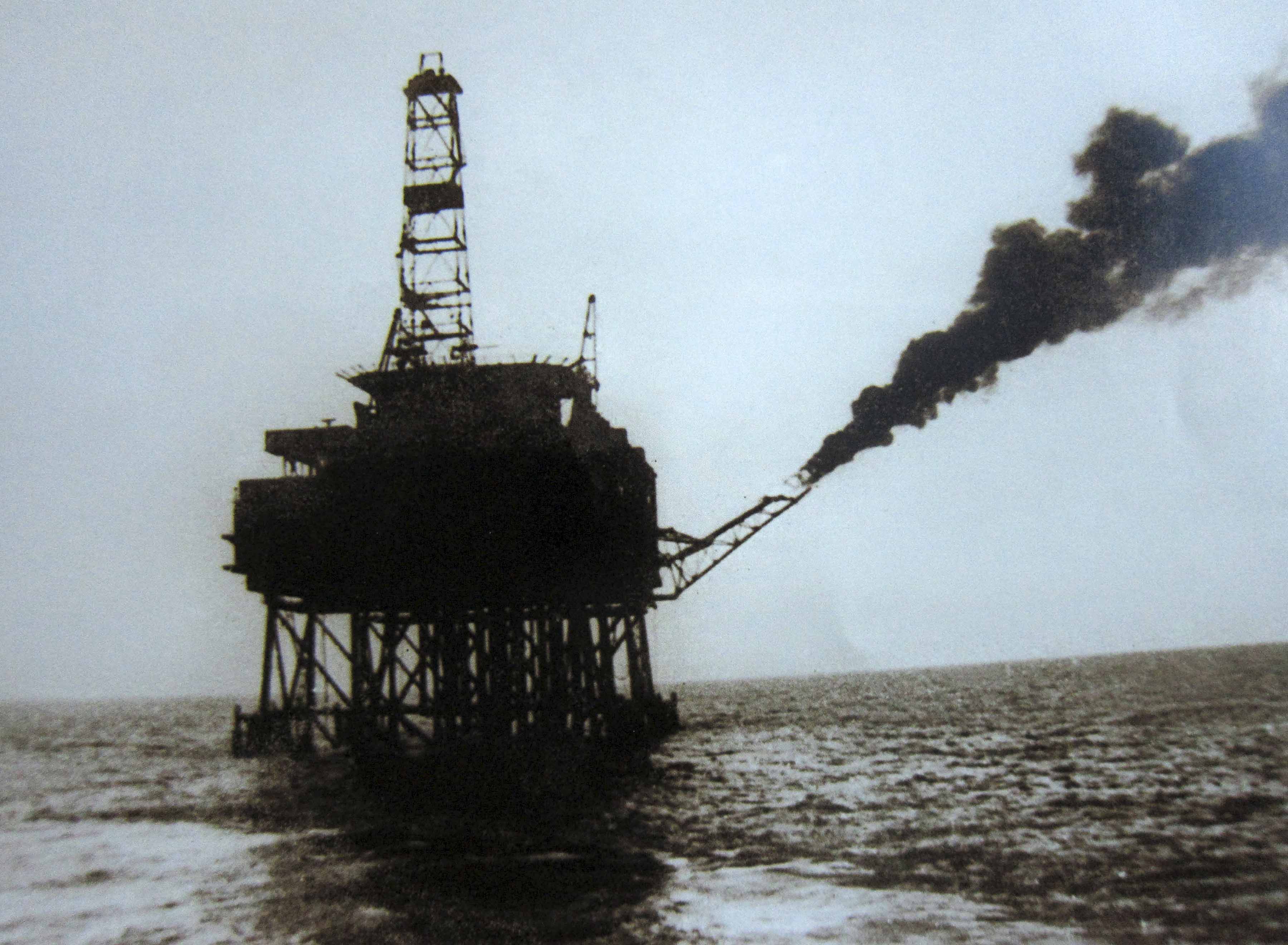

In March 1984, the Steel Structure Enterprise (the predecessor of PVC-MS) and Soviet experts participated in the construction of Vietnam's jacket platform (OB2-MSP1 jacket) to serve Vietsovpetro in extracting the first tons of oil in the Bach Ho oil field.

Despite the numerous difficulties and challenges in the early days of the Vietnam Oil and Gas Construction Industry, with a lack of specialized manpower and experience, inadequate construction machinery and equipment, and inconsistent infrastructure, PVC-MS’s workforce had united and made efforts to learn about science and technology and successfully completed the mission of construcing Vietnam's first jacket platform in Oil and Gas industry. This success laid the foundation for PVC-MS to become a strategic partner of Vietsovpetro in the construction of jackets and topsides for the Vietnamese oil and gas industry.

OB2-MSP1 Jacket

2. Successfully manufacturing the node connection system for tubular steel structures, laying the foundation for complete construction of jacket platforms in Vietnam

In 1984, PVC-MS was assigned the mission of constructing the second drilling platform in Vietnam. At that time, the construction time of the jacket took more than 9 months, and all materials and semi-finished products such as nodes, beams,… had to be imported from the former Soviet Union, and the main works were carried out by Soviet experts. During the construction process, PVC-MS’s leadership, together with its employees, innovated, researched, and self-manufactured all the "nodes" to replace imported products. This was a great success of PVC-MS, affirming that for the first time, a Vietnamese enterprise had demonstrated its internal strength by self-fabricating and assembling drilling platforms in Vietnam meeting international standards without importing semi-finished products from abroad. This shortened the construction time from 9 months to 6 months, reducing costs, lowering prices, and increasing profits for the company.

3. Successfully constructing the first DK1 platform to serve scientific research and marine services in the Truong Sa archipelago

After 1988, the Central Committee assigned the Ministry of Defense to deploy the construction of scientific and technical service clusters in the form of platforms with the name DK1; PVC-MS had the honor to collaborate with Vietsovpetro Joint Venture to construct the first platforms installed in the Truong Sa archipelago during the period 1989-1990. Up to now, PVC-MS has constructed over 90% of the DK platforms, making an important contribution to scientific research and guarding of homeland's islands and seas.

DK1 platform

4. Since 1998, PVC-MS has been the first unit, along with Vietsovpetro, to participate in the construction of the Ruby A platform following international standards. The project achieved safe and efficient quality and construction progress, openning the period of PVC-MS's international cooperation.

With a skilled and experienced workforce in constructing jackets and topsides for the Vietsovpetro Joint Venture, PVC-MS, together with VSP, successfully fabricated the Ruby A platform's topside and jacket for Petronas Carigali (Malaysia) following API standards. This was a significant milestone that allowed PVC-MS to gain valuable experience and open up new service opportunities with foreign partners. The projects implemented by PVC-MS for oil and gas contractors have increasingly shortened the construction schedule, ensuring absolute safety with high economic efficiency.

Ruby A platform

5. Starting to achieve success in the construction of gas pipelines and distribution stations projects.

In 2002, PVC-MS successfully collaborated with its parent company (PVECC) to implement the gas pipeline from Ba Ria to Phu My, the gas distribution stations ensuring a supply of 2 to 3 million cubic meters of gas per day and Thi Vai terminal pipeline. Continuing to leverage its strengths, in 2007, PVC-MS, together with the Vietsovpetro Joint Venture, successfully implemented the PM3 Ca Mau gas pipeline, making a significant contribution to the development of the country's gas industry.

6. Constructing storage tank systems for oil and gas industrial plants and refrigerated LPG tanks with the most advanced technology in Vietnam since 2013.

With experience in constructing storage tank systems for oil and gas industrial plants, Vung Tau, Cu Lao Tao, Can Tho, Thai Binh, Chan May, Lien Chieu, and Nam Dinh Oil terminal,… in 2013, PVC-MS successfully fabricated and installed two central refrigerated LPG tanks with a capacity of 60,000 cubic meters as part of the Thi Vai LPG storage project. These storages were the first in the country to have a vertical cylindrical structure composed of two layers, manufactured using the most advanced technology and also the largest refrigerated LPG storages in Vietnam.

Thi Vai LPG storage

7. Completing operations following the Group model, successfully restructuring the company and focusing on core areas. The management model was transformed from an affiliated enterprise to a single share-holder limited company, and the company has successfully undergone the process of state-owned enterprise equitization.

In 2007, Petroleum Equipment Assembly and Metal Structure Enterprise was transformed into Petroleum Equipment Assembly and Metal Structure Limited Company with a charter capital of 50 billion VND. In 2009, following the policy of Vietnam National Oil and Gas Group and PetroVietnam Construction Joint Stock Corporation, the company underwent equitization with an initial charter capital of 200 billion VND, which has now increased to 600 billion VND.

With the new management model, a new chapter has begun in the company's management work. With a dynamic and innovative team of professionals, PVC-MS has continuously expanded its scale of operations both in breadth and depth, becoming increasingly sustainable.

PVC-MS’s leadership at the IPO ceremony on the HOSE stock exchange - Stock code: PXS

8. Constructing large jackets on record in the oil and gas industry.

In 2010, PVC-MS completed the fabrication of Dai Hung Jacket, which had a water depth of 110 meters and weighed 7,200 tons. This jacket was three times heavier than the typical jackets manufactured in Vietnam, setting a new record in the country at that time.

Dai Hung Jacket

Not stopping there, immediately after the success of Dai Hung Jacket, PVC-MS excellently carried out the construction of Moc Tinh 1 Jacket, which was 136 meters high and weighed over 13,000 tons. This project set a new record in the construction and manufacturing of drilling platforms and was marked with a plaque celebrating the 50th anniversary of the traditional day of Vietnam oil and gas industry by Vietnam National Oil and Gas Group.

Moc Tinh Jacket

9. Investing in the construction of the Complex of High-rise Residential Buildings and Office Buildings, as well as PVC-MS Metal Structure Fabrication Yard

In accordance with the development strategy until 2015 and the vision until 2025, PVC-MS has invested in the construction of a Complex of High-rise Residential Buildings and Office Buildings at 02 Nguyen Huu Canh Street, Vung Tau City. This building complex gave PVC-MS a new appearance, showcasing its sustainable, professional, and long-term stability. It also contributed to building trust among partners, customers, and promoting the image of PVC-MS in business transactions.

Company’s head office

Additionally, the company constructed PVC-MS Metal Structure Fabrication Yard, covering an area of 23 hectares, with a capacity to manufacture 10,000 tons of structures per year and a 246-meter-long jetty which is capable of accommodating vessels up to 10,000 tons. With this infrastructure, PVC-MS has all the necessary facilities to proactively manufacture structures at its own port, enabling the company to directly sign and execute contracts with foreign partners.

Both of these projects have been marked by Vietnam National Oil and Gas Group with plaques celebrating the 50th anniversary of the traditional day of Vietnam oil and gas industry.

PVC-MS Fabrication Yard

10. Becoming one of the main construction contractor in the oil and gas industry.

In 2011, on the newly invested port, with a highly experienced workforce, PVC-MS was assigned for the first time to implement H4 Te Giac Trang Wellhead Platform Topside EPCI package, invested by the Hoang Long - Hoan Vu Joint Operating Company (Hoang Long JOC).

The project was accepted to meet international quality, absolute safety, and a construction progress that was 37 days ahead of schedule, resulting in an early revenue increase of 66 million USD for the investors. The success of this project marked PVC-MS's transition from a construction contractor to an EPCI (Engineering, Procurement, Construction, and Installation) contractor. This milestone signifies PVC-MS's remarkable growth and opens up new development opportunities in executing EPCI contracts in the oil and gas industry.

H4 Wellhead Platform Topside

11. Successfully manufacturing high-tech equipment in Oil and Gas exploitation sector.

After achieving many successes in the construction of drilling platforms and various types of oil and gas storage with diverse and modern technology, PVC-MS has begun to penetrate deeply and successfully in the field of manufacturing and supplying oil extraction equipment such as Chemical Injection Skid, Pressure Vessel, Flowline, and E-House,…opening up a new product manufacturing sector in PVC-MS's strategic development plan.

12. At the end of 2019, PVC-MS was the only Vietnamese contractor to collaborate with POSCO E&C in forming a consortium to undertake Package A2, "Tank Farm and Interconnecting Pipelines," in Southern Petrochemical Complex Project (Long Son Petrochemical).

Southern Petrochemical Complex Project (Long Son Petrochemical) is a project capable of producing up to 1.6 million tons of olefin products per year. PVC-MS's scope of work in Package A2, - with a contract value of over 2,800 billion VND and nearly 4 years of construction time, included detailed design, procurement, fabrication, and installation of a total of 25 tanks (including 10 cylindrical tanks, 12 spherical tanks, and 3 floating roof tanks). It also included the fabrication and installation of steel structures with a total weight of 12,887 tons and a total length of 5.8km, as well as the installation of equipment weighing 1,683 tons and a technological pipeline system of 814,000 DI, equivalent to 460km.

Long Son project execution overview

Up to now, Package A2 is the largest-scale project that PVC-MS has ever implemented, from construction site to work volume, many items, subcontractors (including 44 contractors), and simultaneous construction activities. Overcoming these challenges has enhanced PVC-MS's capabilities in construction control, subcontractor management, and specialized fields.

During the project execution period, despite the global COVID-19 pandemic from 2019 to 2022, which affected the construction progress, PVC-MS maximized its internal strengths, maintained close coordination with the Consortium member, POSCO E&C, as well as the investor, LSP, and adjusted construction measures to ensure optimal solutions. By June 2022, Package A2 was handed over to the investor, marking the first and earliest on-schedule delivery milestone of the project. This achievement has elevated the PVC-MS brand to new heights, opening up new job opportunities for future projects.

13. Affirming the PVC-MS brand in participating in the construction of Thai Binh 2 Thermal Power Plant Project.

Following the successful completion of structures and electromechanical works at Nhon Trach 2 Thermal Power Plant, Dung Quat Oil Refinery Plant, and Polypropylene Plant, as well as the SMP1 package at Nghi Son Refinery and Petrochemical Complex, where PVC-MS was recognized as the best contractor among the participating contractors. In 2014, PVC-MS was selected to participate in Thai Binh 2 Thermal Power Plant project as the contractor responsible for some key features. The project is led by Vietnam National Oil and Gas Group as the investor and PetroVietnam Construction Joint Stock Corporation as the EPC contractor undertaking the construction, commisioning and handover.

In Thai Binh 2 Thermal Power Plant project, PVC-MS has reaffirmed its position as a leading provider of high-quality services in the specialized field of oil and gas construction, with a focus on mechanical, electrical, instrumentation and installation of heavy equipment within the power plant.

Alongside the fabrication of steel structures for turbine houses and control centers, in July 2015, PVC-MS commenced one of the most critical package: the electromechanical installation for Unit 2 of Thai Binh 2 Thermal Power Plant. This package included the installation of turbine, generator, and auxiliary equipment for Unit 2, as well as installation of water supply tank system, deaerator tank weighing 132 tons at a height of 28 meters, low-pressure and high-pressure heat exchangers, condenser tank, and a technological pipeline system. Notably, the stator of the Unit 2 generator, weighing a total of 340 tons, was lifted to a height of 17.8 meters by PVC-MS, moved 38 meters, and then installed. This method was the most optimal for handling heavy equipment. With great effort, PVC-MS successfully and safely completed the installation of the generator for Unit 2 ahead of the schedule.

In addition to maintaining and developing its offshore oil and gas construction services, the successful installation of Unit 2 at Thai Binh 2 Thermal Power Plant and Nghi Son Refinery and Petrochemical Complex have extremely important significance, marking a major step forward in the development of PVC-MS. These achievements have provided valuable experience and maturity, enabling PVC-MS to keep moving forward with petrochemical plant projects.

Thai Binh 2 Thermal Power Plant execution overview

14. Some notable achievements have been recognized

With all the above achievements, PVC-MS has been honored with the First, Second, and Third Class Labor Medals, as well as the Fatherland Defense Medal. In 2013, PVC-MS was awarded the Independence Medal by the President of Vietnam for its outstanding achievements and significant contributions to the cause of building socialism and defending the Socialist Vietnamese Fatherland.

In 2011, PVC-MS was voted by Forbes magazine as one of the Top 200 small and medium-sized enterprises in the Asia-Pacific region.

In 2012, PVC-MS was ranked 169th among the Top 1,000 000 Enterprises paying the largest corporate income tax in Vietnam, as voted by Vietnam Report Joint Stock Company.

These achievements, recognized by both the Vietnamese government and reputable international organizations, demonstrate the success and reputation of PVC-MS in various aspects of its operations.

Some images of awards, the Independence Medal, and certificates

PVC-MS