.jpg)

PVC-MS participated in executing Package A2 of the Long Son Petrochemical Complex Project at the end of 2019. After one year of construction, the project progress has reached nearly 60%, with several items exceeding the planned schedule. Package A2 is one of the key components of the Long Son Petrochemical Complex Project.

The Long Son Petrochemical Complex Project (located in Long Son Commune, Vung Tau City) is invested by Long Son Petrochemicals Co., Ltd., covering approximately 464 hectares of land and 194 hectares of water surface for port facilities, with a total investment of 5.4 billion USD. The project commenced in 2018, with a planned construction duration of 5 years.

Long Son Petrochemical Complex Project

This is the first petrochemical complex in Vietnam with an olefin production capacity of up to 1.6 million tons per year. The project is invested to produce a wide range of petrochemical products, including raw materials essential for the plastics industry (such as polyethylene and polypropylene), as well as other products with a total capacity of over 2 million tons per year, capable of replacing polyethylene products currently being imported. With its large scale and investment, the project is expected to become a modern petrochemical hub in the southern region, contributing significantly to the economic development of Ba Ria–Vung Tau Province and serving as a driving force for national growth.

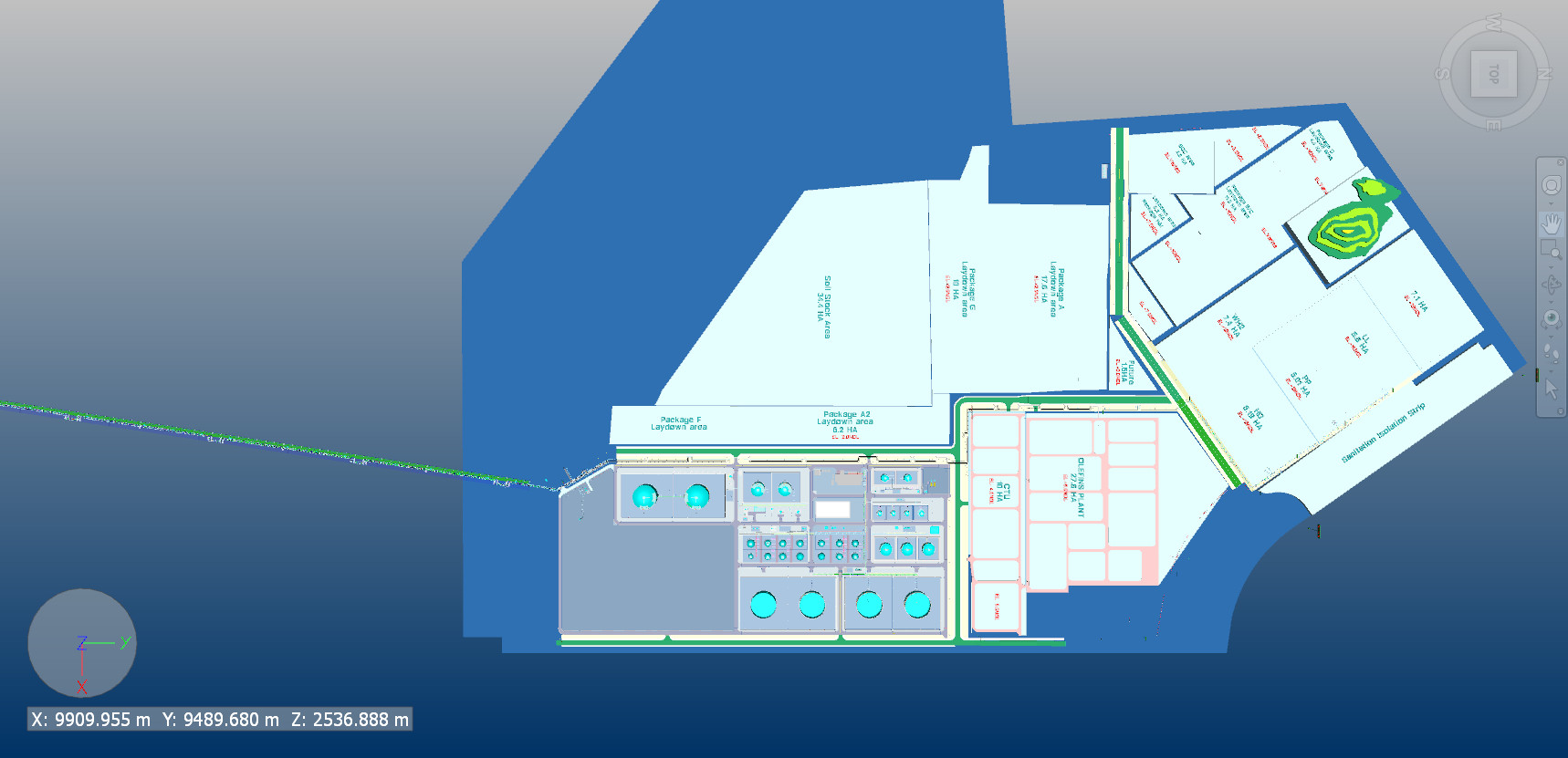

The project consists of over ten major components corresponding to different contract packages. PVC-MS and POSCO E&C form the consortium serving as the main contractor for the Tank and Interconnecting Pipeline Package (A2) – one of the project’s most important components. This package is extensive in scale and scope (running around the project area), including the tank area, structural works, various equipment, pipe supports, and interconnecting pipelines stretching from the import/export terminal to all processing areas of the plant.

The scope of work for PVC-MS in this package includes: design, material procurement, fabrication, and installation of 12 spherical tanks, 10 domed roof tanks, and 3 floating roof tanks; fabrication, installation, and pre-commissioning of the Piping system totaling 844,243 dia-inch; procurement and execution of piping painting of 569,896 m²; fabrication and installation of 10,143 tons of steel structures; procurement and installation of piping insulation of 122,838 meters; and installation of mechanical equipment and fire-fighting equipment totaling 1,676 tons.

A section of Package A2 – Long Son Petrochemical Complex executed by PVC-MS

Despite having many advantages in its areas of expertise, PVC-MS has faced various difficulties and challenges during execution. As of now, Package A2 is the largest-scale package ever undertaken by PVC-MS, with construction sites spread throughout the project, large workloads, multiple components, many subcontractors (44 subcontractors), and concurrent construction timelines—all of which have significantly affected construction deployment, control, and subcontractor coordination. The complicated developments of the COVID-19 pandemic have directly impacted material supply progress for the package. New work areas beyond PVC-MS’s core strengths and differences from previous projects have also posed challenges for the engineering and worker teams.

However, with determination to successfully complete the package, PVC-MS has fully utilized its internal strengths, implemented optimal solutions, prepared detailed plans, and adjusted construction measures appropriately. The company selected elite engineers, skilled workers, and experienced safety/quality control personnel with international certifications in welding, NDE, painting, insulation, etc. For this project, PVC-MS applied an integrated quality and safety management system per ISO 45001, OSHA international safety standards, and strictly complied with the investor’s stringent requirements consistent with IFC standards.

The jetty and part of the interconnecting pipeline system of Package A2

Thanks to consistent efforts and strict procedures, PVC-MS has currently achieved the milestone of one million safe working hours. Project progress has reached nearly 60%, with many items ahead of schedule, including Structural Works (6.294% ahead); Tanks (7.517% ahead); Interconnecting Pipeline System (15.366% ahead); Firefighting Pipeline System (17.912% ahead); Painting Works (13.400% ahead); and Insulation Works (12.287% ahead).

Package A2 has brought PVC-MS a stable workload and ensured completion of the 2020 business targets. At the same time, the new areas outside PVC-MS’s traditional expertise have helped engineers and workers gain more experience, improve competency, and become more capable and confident in competing for future projects.

According to the plan, by the end of 2022, the components of Package A2 will be completed, commissioned, and handed over to the investor. The Long Son Petrochemical Complex is expected to begin commercial operation in early 2023. Currently, PVC-MS is concentrating efforts to execute the package in the best possible manner to contribute to the overall project schedule.