1. After a long period of accumulation and persistent development, Petrovietnam has now fully converged the core foundations for genuine self-reliance: high-quality human resources, robust science and technology capabilities, extensive experience in implementing large-scale projects, and an increasingly synchronized technical infrastructure system. This requirement for self-reliance is driven not only by the unpredictable fluctuations in the energy market but also by the inevitable demand to optimize resources, maximize internal strength, and enhance competitiveness in the new context.

Between 2022 and 2025, numerous key projects and works were deployed and successfully completed despite the exceptionally harsh conditions of the global energy market. This clearly reveals a compelling picture: Petrovietnam has truly mastered the most essential phases of the mega-scale, heavy-lift construction chain within the oil, gas, and energy sectors.

The most distinct mark of self-reliance in the Exploration and Production (E&P) sector in 2025 was the Dai Hung Phase 3 Field Development Project. A field that once faced the risk of cessation has now entered a new, sustainable, and promising development cycle. Dai Hung Phase 3 is not the largest project in terms of scale or reserves, but it is a clear symbol of the internal strength of Petrovietnam's workforce, as the entire process—from design and fabrication to execution and operation—was mastered by the core units within the Group’s ecosystem.

The moment the first commercial oil flow was received on May 7, 2025, represented the culmination of overcoming a "twin storm" of Covid-19, supply chain disruption, and geopolitical instability. As the EPCI general contractor, the Russia-Vietnam Joint Venture - Vietsovpetro closely collaborated with the Petrovietnam Technical Services Corporation (PTSC), Petrovietnam Drilling and Well Services Corporation (PV Drilling), and the field operator, PVEP Domestic Operating Branch (PVEP-POC). Given the characteristics of the deep-water, far-offshore field with infrastructure operating for over 30 years, PVEP-POC proactively optimized the design, reused existing infrastructure, localized equipment, and mobilized resources within the Petrovietnam ecosystem. This brought the project to a safe and economically efficient completion, marking it as one of the standout E&P self-sufficiency milestones during the Group's 50th anniversary of formation and development.

Most recently, Petrovietnam's self-reliance capability was further asserted through the colossal steel structures of the Block B Central Processing Platform (CPP) jacket and topside project. The project involves a jacket weighing approximately 7,400 tons and piles weighing nearly 5,700 tons, with a total investment value exceeding 3,300 billion VND. The entire structure was fabricated entirely domestically by PTSC, specifically the PTSC Mechanical & Construction Company (PTSC M&C), involving nearly 1,000 engineers and workers. Behind these mega-scale, heavy-lift steel blocks is a complex technological system: structural design for high load-bearing capacity in a marine environment, heavy-section steel welding technology, thermal deformation control, and a multi-layer protective coating system to ensure a lifespan of several decades offshore.

The timely completion of the structure not only marks a crucial milestone in the Block B Gas Project's implementation journey but also demonstrates the competence, resilience, and determination of Petrovietnam and its member units in executing this national key energy project. Simultaneously, this success affirms the increasingly strong position of Vietnam's petroleum engineering sector in the mega-scale, heavy-lift offshore structure segment.

2. Internal capability is also evident in the ability to organize synchronous construction and optimize the schedule for the BK-24 platform by the Vietsovpetro Joint Venture. This is the second field development structure Vietsovpetro completed in 2025. From design, and fabrication of the jacket and topside to offshore installation were directly carried out by the OFFSHORE CONSTRUCTION DIVISION (OCD) of Vietsovpetro. The achievement of welcoming the commercial oil flow 65 days ahead of schedule is both a timeline feat and a reflection of the ability to master the tempo of EPCI execution—one of the biggest challenges in modern exploration and production facilities.

Meanwhile, the Kinh Ngu Trang – Kinh Ngu Trang Nam (White Whale – Southern White Whale) Project in Block 09-2/09 showcases self-reliance in the synchronized organization of an entire cluster of complex marginal fields. The project involves Vietsovpetro, Petrovietnam Exploration Production Corporation (PVEP), and OA Zarubezhneft, with Vietsovpetro serving as the Operator. The project encompasses the entire chain of items, from the CPP-KNT central platform and the WHP-KTN minimal platform to the pipeline system, subsea cables, and modification of existing platforms, demanding high technical and organizational standards.

By optimizing design, flexible construction methods, and maximizing internal resources, Vietsovpetro successfully completed the Kinh Ngu Trang – Kinh Ngu Trang Nam Project ahead of schedule. Launched on June 7, 2023, the project faced immense scheduling pressure amidst the pandemic, geopolitical conflicts, and supply chain disruptions, which forced many components to be executed in parallel, or even transferred offshore instead of being completed onshore. Bringing the Kinh Ngu Trang – Kinh Ngu Trang Nam field into commercial exploitation helps maintain production in the context of declining nearby fields and carries strategic significance for energy security and national sovereignty.

In a recent statement, Mr. Le Manh Hung – Chairman of the Board of Members of Petrovietnam, emphasized that the Exploration and Production (E&P) sector is the Group’s crucial driving force until 2035. Therefore, Petrovietnam needs to continue focusing on generating growth momentum for E&P through accelerating investment, technological innovation, and increasing reserves and production output. In this landscape, the successfully mastered mega-scale, heavy-lift projects are not just the "sweet fruit" of accumulated experience but also the foundation for Petrovietnam to continue breaking through on the E&P pillar—the strategic driver of the Group in the decades to come.

3. Petrovietnam’s self-reliance capacity is not limited to traditional oil and gas. It has expanded into the renewable energy sector, with PTSC successfully acting as the general contractor for the fabrication of 33 offshore wind foundation jackets for the Taiwan (China) market. Transitioning from the unit-based production model of oil and gas to the mass production model of wind power required a genuine "technological transformation" concerning technology, yard space, equipment, and technical standards. When the final batch of foundations was handed over in June 2025, the greatest value was not just a successful international contract but the formation of a renewable energy mechanical engineering capacity built upon Petrovietnam/PTSC’s oil and gas foundation.

.jpg)

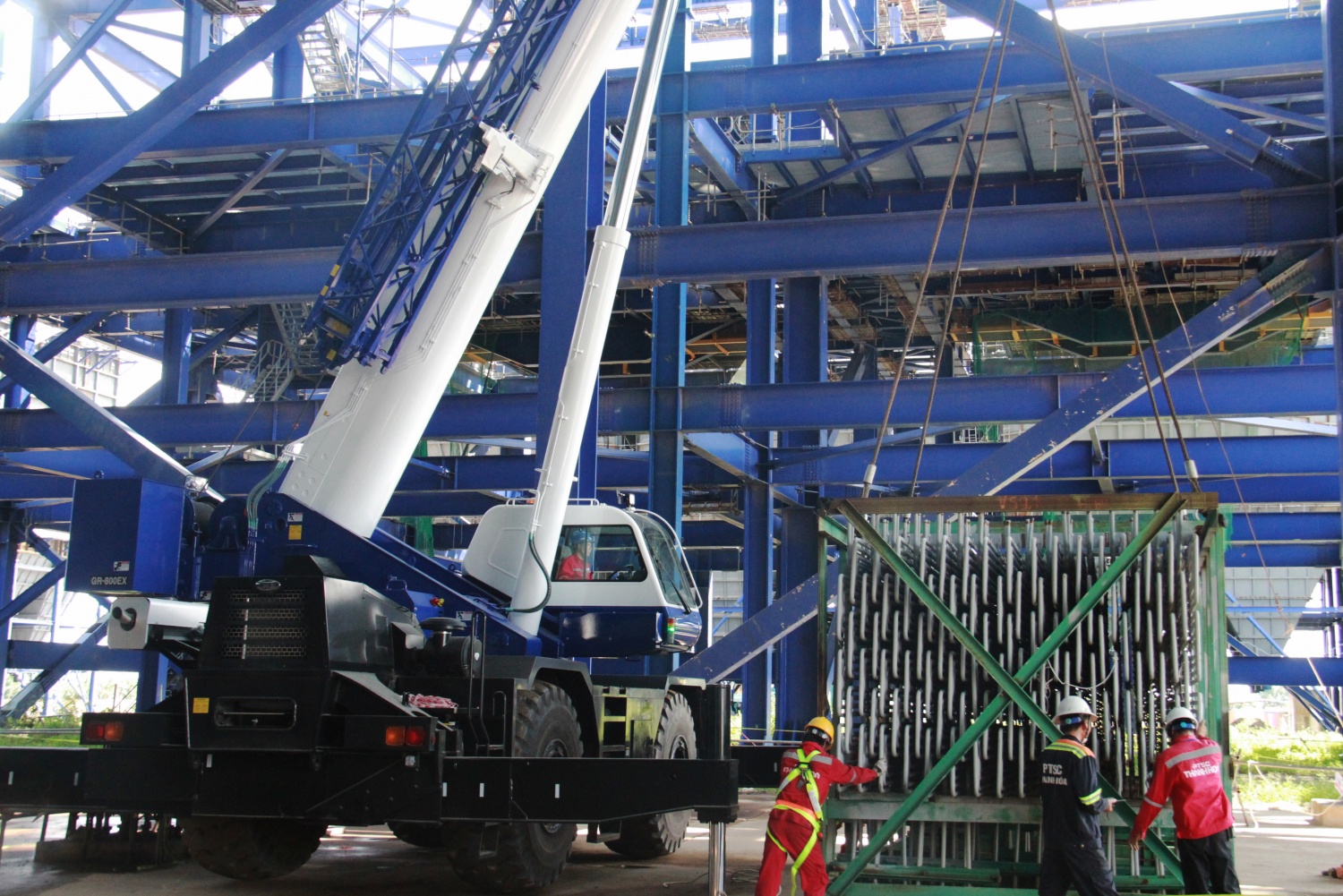

Parallel to the major offshore projects, another direction for self-reliance is forming onshore through the general contractor joint venture model between PTSC and Petrovietnam Construction Joint Stock Corporation (PETROCONS) for the Long Phu 1 Thermal Power Plant Project. This is considered the initial step for Petrovietnam’s role as the EPC general contractor for large-scale onshore energy projects, contributing to the gradual completion of a competence chain: from self-mastery of marine structure design and fabrication to general contracting for the construction of industrial and energy plants.

The projects completed in 2025 are significant not only in terms of production output or economic value but, more profoundly, they mark a qualitative shift in Petrovietnam's capacity to master the core areas of the industrial and energy sectors. From deep and far offshore to heavy steel structures weighing tens of thousands of tons onshore, Petrovietnam's scientific-technological competence and construction organization ability have been tested and affirmed by practical reality.

Under the leadership of the Party and the Goverment, Petrovietnam has accompanied the nation for 50 years, acting as a driving force for national economic and social development by fulfilling its mission of ensuring "5 Securities" (5 An): energy security, economic security, food security, defense/national security, and national sovereignty at sea, while also contributing to social welfare.

By implementing this 5-"Security" mission, Petrovietnam has asserted the prestige and position of a leading national economic group with "5 Highests" :

Largest Scale: Consolidated total assets exceeding 1 quadrillion VND (over $40 billion), with owner’s equity of more than 556 trillion VND.

Highest Budget Contributor: Averaging 160 trillion VND per year in recent years, accounting for 80.3% of the total budget contributions of the 18 Groups and Corporations within the state-owned enterprise sector.

Highest Profit: Achieving 316 trillion VND in profit during the 2020-2025 period, equivalent to an average of $2.2 billion per year.

Most Awarded for S&T: The only enterprise to win and achieve numerous high-level awards in science and technology, including 6 Ho Chi Minh Prizes and 4 State Prizes, along with dozens of prestigious domestic and international patents.

Leading in Social Welfare: The enterprise that leads and achieves the highest level in social welfare activities, dedicating over 5.13 trillion VND to this activity in the 2020-2025 period alone.

Translated from Petrotimes - Le Truc.